慧学(68):精读期刊论文消费者到制造商模式

分享兴趣,传播快乐,

增长见闻,留下美好!

亲爱的您,这里是LearningYard学苑。

今天小编为大家带来

“慧学(68):精读期刊论文《When Triple-A Supply Chains Meet Digitalization: The Case of JD.com’s C2M Model》消费者到制造商模式”。

欢迎您的访问!

Share interest, spread happiness,

increase knowledge, and leave beautiful.

Dear, this is the LearningYard Academy!

Today, the editor brings the

“Hui Xue (68): Intensive reading of the journal article ‘When Triple-A Supply Chains Meet Digitalization: The Case of JD.com’s C2M Model’ consumer to manufacturer model”.

Welcome to visit!

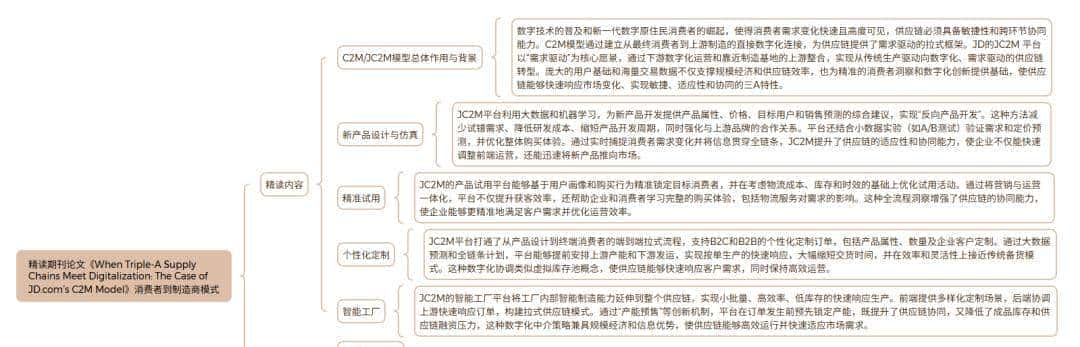

本期推文小编将从思维导图、精读内容、知识补充三个方面为大家介绍期刊论文《When Triple-A Supply Chains Meet Digitalization: The Case of JD.com’s C2M Model》的消费者到制造商模式。

In this issue, the editor will introduce the consumer to manufacturer model of the journal article “When Triple-A Supply Chains Meet Digitalization: The Case of JD.com’s C2M Model” from three aspects: mind mapping, intensive reading content, and knowledge supplement.

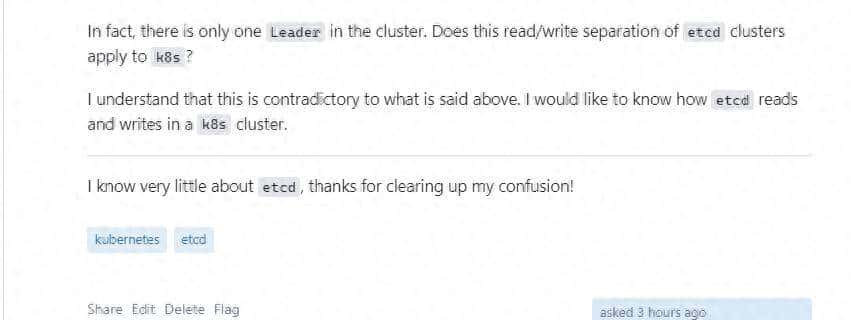

一、思维导图(Mind mapping)

二、精读内容(Intensive reading content)

1、C2M/JC2M模型总体作用与背景(Overall role and background of c2m/jc2m models)

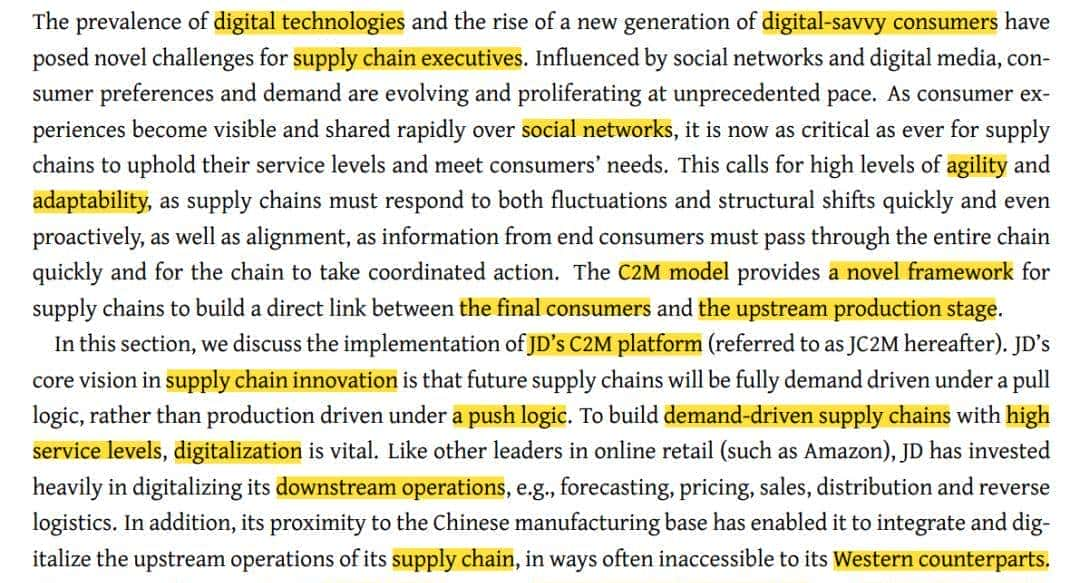

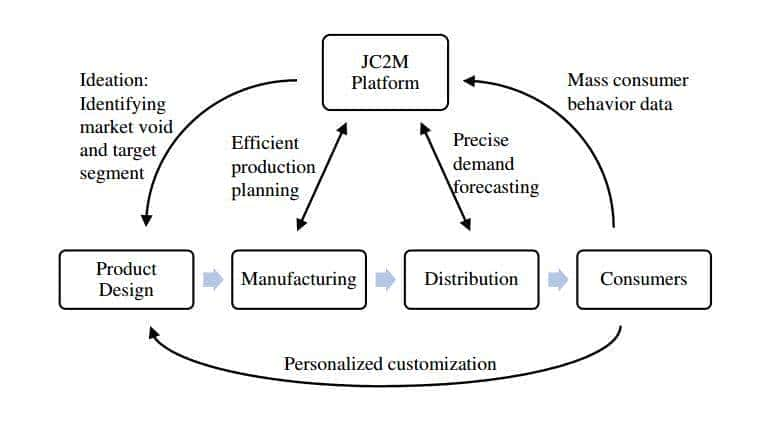

数字技术的普及和新一代数字原住民消费者的崛起,使得消费者需求变化快速且高度可见,供应链必须具备灵敏性和跨环节协同能力。C2M模型通过建立从最终消费者到上游制造的直接数字化连接,为供应链提供了需求驱动的拉式框架。JD的JC2M 平台以“需求驱动”为核心愿景,通过下游数字化运营和靠近制造基地的上游整合,实现从传统生产驱动向数字化、需求驱动的供应链转型。庞大的用户基础和海量交易数据不仅支撑规模经济和供应链效率,也为精准的消费者洞察和数字化创新提供基础,使供应链能够快速响应市场变化、实现灵敏、适应性和协同的三A特性。

The widespread adoption of digital technologies and the rise of a new generation of digitally native consumers have made changes in consumer demand rapid and highly visible, requiring supply chains to possess agility and cross-segment collaboration capabilities. The C2M (Consumer-to-Manufacturer) model provides a demand-driven pull framework for the supply chain by establishing direct digital connections from end consumers to upstream manufacturers. JD's JC2M platform, with “demand-driven” as its core vision, achieves a transformation from traditional production-driven to a digital, demand-driven supply chain through downstream digital operations and upstream integration close to manufacturing bases. A massive user base and vast amounts of transaction data not only support economies of scale and supply chain efficiency but also provide the foundation for precise consumer insights and digital innovation, enabling the supply chain to respond quickly to market changes and achieve the three key characteristics of agility, adaptability, and collaboration.

2、新产品设计与仿真(New product design and simulation)

JC2M平台利用大数据和机器学习,为新产品开发提供产品属性、价格、目标用户和销售预测的综合提议,实现“反向产品开发”。这种方法减少试错需求、降低研发成本、缩短产品开发周期,同时强化与上游品牌的合作关系。平台还结合小数据实验(如A/B测试)验证需求和定价预测,并优化整体购买体验。通过实时捕捉消费者需求变化并将信息贯穿全链条,JC2M提升了供应链的适应性和协同能力,使企业不仅能快速调整前端运营,还能迅速将新产品推向市场。

The JC2M platform leverages big data and machine learning to provide comprehensive suggestions for new product development, including product attributes, pricing, target users, and sales forecasts, enabling “reverse product development.” This approach reduces the need for trial and error, lowers R&D costs, shortens product development cycles, and strengthens partnerships with upstream brands. The platform also incorporates small-scale experiments (such as A/B testing) to validate demand and pricing forecasts and optimize the overall buying experience. By capturing real-time changes in consumer demand and integrating this information throughout the entire supply chain, JC2M enhances the adaptability and collaboration of the supply chain, enabling companies to not only quickly adjust front-end operations but also rapidly launch new products to market.

3、精准试用(Precise trial)

JC2M的产品试用平台能够基于用户画像和购买行为精准锁定目标消费者,并在思考物流成本、库存和时效的基础上优化试用活动。通过将营销与运营一体化,平台不仅提升获客效率,还协助企业和消费者学习完整的购买体验,包括物流服务对需求的影响。这种全流程洞察增强了供应链的协同能力,使企业能够更精准地满足客户需求并优化运营效率。

JC2M's product trial platform accurately targets consumers based on user profiles and purchasing behavior, optimizing trial activities while considering logistics costs, inventory, and delivery time. By integrating marketing and operations, the platform not only improves customer acquisition efficiency but also helps businesses and consumers learn about the complete buying experience, including the impact of logistics services on demand. This end-to-end insight enhances supply chain collaboration, enabling businesses to more accurately meet customer needs and optimize operational efficiency.

4、个性化定制(Personalized customization)

JC2M平台打通了从产品设计到终端消费者的端到端拉式流程,支持B2C和B2B的个性化定制订单,包括产品属性、数量及企业客户定制。通过大数据预测和全链条计划,平台能够提前安排上游产能和下游发运,实现按单生产的快速响应,大幅缩短交货时间,并在效率和灵活性上接近传统备货模式。这种数字化协调类似虚拟库存池概念,使供应链能够快速响应客户需求,同时保持高效运营。

The JC2M platform streamlines the end-to-end pull process from product design to the end consumer, supporting personalized customization orders for both B2C and B2B, including product attributes, quantities, and enterprise customer customization. Through big data forecasting and end-to-end planning, the platform can pre-arrange upstream production capacity and downstream shipments, enabling rapid response through make-to-order production, significantly shortening delivery times, and approaching the efficiency and flexibility of traditional inventory-based models. This digital coordination, similar to the concept of a virtual inventory pool, allows the supply chain to respond quickly to customer needs while maintaining efficient operations.

5、智能工厂(Smart factory)

JC2M的智能工厂平台将工厂内部智能制造能力延伸到整个供应链,实现小批量、高效率、低库存的快速响应生产。前端提供多样化定制场景,后端协调上游快速响应订单,构建拉式供应链模式。通过“产能预售”等创新机制,平台在订单发生前预先锁定产能,既提升了供应链协同,又降低了成品库存和供应链融资压力,这种数字化中介策略兼具规模经济和信息优势,使供应链能够高效运行并快速适应市场需求。

JC2M's smart factory platform extends the factory's intelligent manufacturing capabilities to the entire supply chain, enabling rapid response production with small batches, high efficiency, and low inventory. The front end provides diverse customization scenarios, while the back end coordinates upstream suppliers to quickly respond to orders, building a pull supply chain model. Through innovative mechanisms such as “capacity pre-sales,” the platform pre-locks capacity before orders are placed, improving supply chain collaboration and reducing finished goods inventory and supply chain financing pressure. This digital intermediary strategy combines economies of scale and information advantages, enabling the supply chain to operate efficiently and adapt quickly to market demands.

三、知识补充(Knowledge supplementation)

1、反向产品开发(Reverse product development)

反向产品开发是一种以消费者需求为核心、从市场需求倒推产品设计和生产的开发方法,其基本思想是“先了解消费者想要什么,再设计和生产产品”,与传统的“先设计、再销售”的模式形成鲜明对比。在这一过程中,企业通过分析大量消费者行为数据、市场趋势和竞争环境,识别未被满足的需求或市场空白,并预测潜在销量、最优价格和目标用户群体,再将这些信息直接应用于产品设计、生产规划和营销策略。这种方法的优势在于可以大幅降低研发试错成本、缩短新产品上市周期,同时增强供应链上下游的协同能力,使生产、采购和分销环节能够提前做好准备,实现快速响应市场需求。

Reverse engineering is a development methodology that focuses on consumer needs and works backward from market demand to design and produce products. Its core idea is “understand what consumers want first, then design and produce the product,” a stark contrast to the traditional “design first, then sell” model. In this process, companies analyze vast amounts of consumer behavior data, market trends, and the competitive landscape to identify unmet needs or market gaps, predict potential sales volume, optimal pricing, and target user groups, and then directly apply this information to product design, production planning, and marketing strategies. The advantages of this approach include significantly reducing R&D trial-and-error costs, shortening new product launch cycles, and enhancing collaboration across the supply chain, enabling production, procurement, and distribution to prepare in advance and respond quickly to market demands.

2、按单生产(Made to the order)

按单生产是一种根据客户实际订单进行生产的供应链模式,其核心理念是“需求驱动生产”,企业在收到客户订单后才开始生产商品,而不是提前大量生产库存。这一模式能够最大化满足客户的个性化需求,提高产品的定制化程度,同时降低库存风险和资金占用。不过,传统MTO模式一般存在交货周期较长的问题,需要企业具备灵活的生产计划和快速响应能力。随着数字化技术的应用,按单生产不仅能够满足个性化需求,还能显著缩短交货时间,使其效率接近传统备货模式。MTO广泛应用于家具、服装、汽车等需要定制化配置的行业,能够提升客户满意度,同时减少库存和财务压力。在实践中,数字化供应链通过提前规划生产和运输,将传统的按单生产模式转化为快速响应体系,使企业在保证灵活性的同时兼顾效率和成本控制,成为现代供应链管理的重大手段和创新案例。

Made-to-the-order (MTO) is a supply chain model where production is based on actual customer orders. Its core concept is “demand-driven production,” where companies only begin manufacturing after receiving customer orders, rather than producing large quantities of inventory in advance. This model maximizes the fulfillment of customers' personalized needs, increases product customization, and reduces inventory risk and capital tied up. However, traditional MTO models typically suffer from long delivery cycles, requiring companies to have flexible production planning and rapid response capabilities. With the application of digital technologies, MTO not only meets personalized needs but also significantly shortens delivery times, bringing its efficiency close to that of traditional pre-stocked models. MTO is widely used in industries requiring customized configurations, such as furniture, apparel, and automobiles, improving customer satisfaction while reducing inventory and financial pressure. In practice, digital supply chains, through advance planning of production and transportation, transform the traditional MTO model into a rapid response system, enabling companies to maintain flexibility while ensuring efficiency and cost control, becoming an important tool and innovative case in modern supply chain management.

今天的分享就到这里了,

如果您对文章有独特的想法,

欢迎给我们留言,

让我们相约明天。

祝您今天过得开心快乐!

That's all for today's sharing.

If you have a unique idea about the article,

please leave us a message,

and let us meet tomorrow.

I wish you a nice day!

翻译:Google翻译

参考资料:百度、Chatgpt

参考文献: Ho Yinmak, Zuo Junmaxshen. When triple‐A supply chains meet digitalization: The case of JD. com's C2M model [J]. Production and Operations Management, 2021, 30(3): 656-665.

本文由LearningYard学苑整理发出,如有侵权请在后台留言!

文案|chen

排版|chen

审核|hzy

相关文章